How to Get the Most Out of Your Grinding Wheel - THE BLUE PRINT

New technology will continue to evolve but applying the appropriate safety precautions and proper usage won’t change when grinding abrasives.

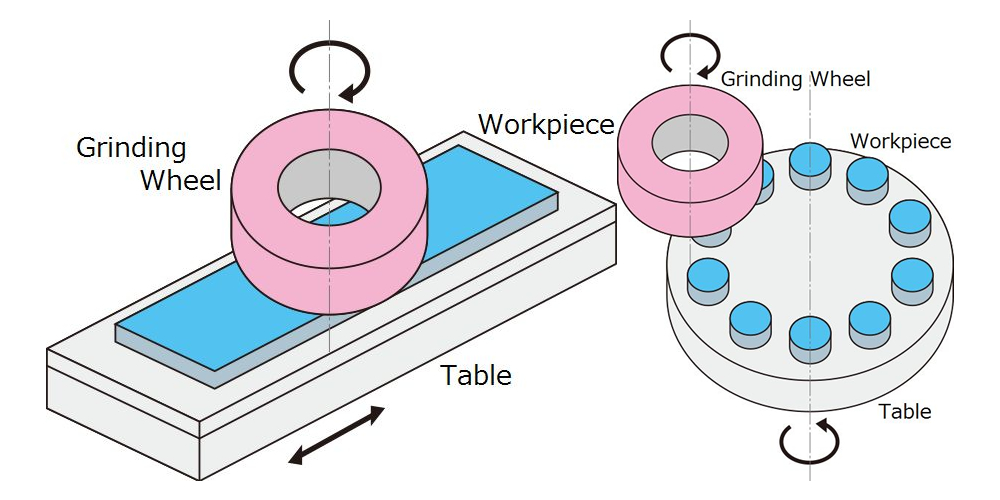

Various grinding methods|A.L.M.T. Corp.

Diamond Grinding Disc Polishing Strip Disc Abrasive Wheels - Temu

PREMIUM QUALITY: These angled flap discs, also known as cut off wheels 4 1/2 inch, are constructed with industrial grade premium zirconia abrasive for

NEIKO 11142A 10 Pack Zirconia Flap Discs 4-1/2 for Angle Grinder, 40 Grit Flapper Wheel, Angled T29 Grinding Wheel 4.5 Inch Flap Disc, 7/8 Arbor

Rebuilding and Improving a 100 Year Old Grinding Wheel

3M™ Vitrified Grinding Wheel 92VA

Optimize Grinding Processes with Proper Truing and Dressing Tools

New approach for cooling and lubrication in dry machining on the example of internal cylindrical grinding of bearing rings - ScienceDirect

4 types of surface grinder machine and their abrasive method-Mrbrianzhao

Grinding wheels are sensitive to vibration due to their mass and speed. The faster your grinder, the more necessary it is to balance wheels. Truly

Oneway 5/8 in. Grinding Wheel Balancing System

i.ytimg.com/vi/WFXvqMyTf-U/maxresdefault.jpg?sqp=

8 Types of Grinding Wheel Breakage Causes and Solutions

Ultimate Guide – Aluminum - Fabrication, Grinding, and Finishing with Abrasives - Empire Abrasives

Avanti Pro 4-1/2 in. x 5/8 in. -11 in. Non-Woven Quick-Strip Disc PNW045STRB01G - The Home Depot

How to Remove Rust From Metal - From Natural DIY to Power Tools - Empire Abrasives

3M™ Cubitron™ II Vitrified Grinding Wheel 92VC