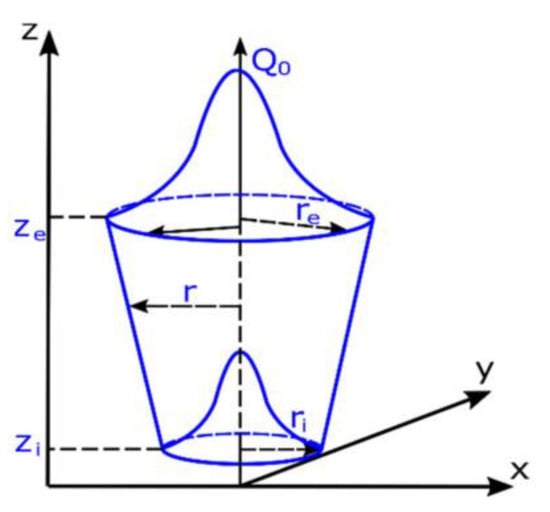

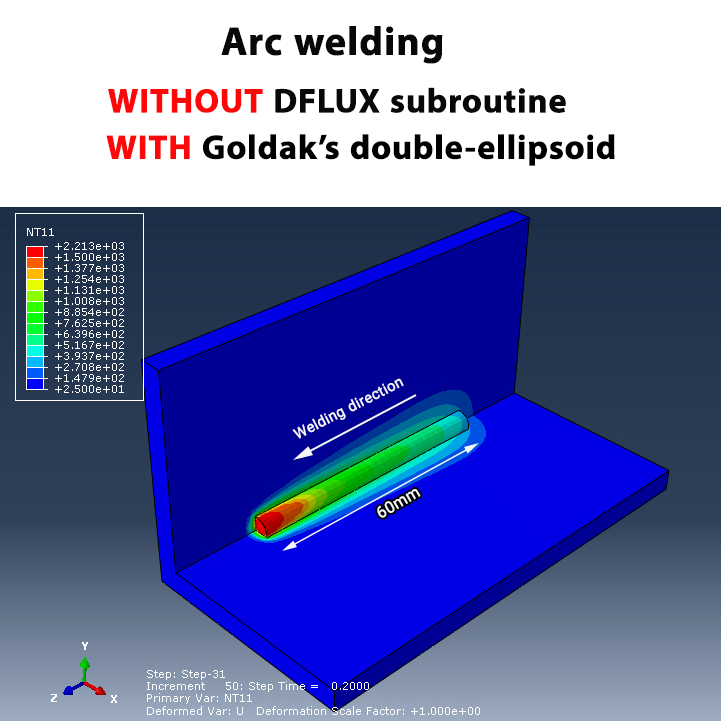

Temperature contour (a) Goldak Double Ellipsoidal (b) Conical (c) CCC

Polymers, Free Full-Text

PDF) Determination of heat source model for simulating full penetration laser welding of 316 LN stainless steel by computational fluid dynamics

Simulation set up showing welding coordinate system and boundary

M. VASUDEVAN, Head, Advanced Welding Processes and Modeling Section, B.E, M.E, PhD, Indira Gandhi Centre for Atomic Research, Chennai, IGCAR, Metallurgy and Materials group (MMG)

Development of avocado shape heat source model for finite element based heat transfer analysis of high-velocity arc welding process - ScienceDirect

Simulation Arc welding using the Goldak's double-ellipsoid heat source model Abaqus – Abaqus Tutorials

M. VASUDEVAN, Head, Advanced Welding Processes and Modeling Section, B.E, M.E, PhD, Indira Gandhi Centre for Atomic Research, Chennai, IGCAR, Metallurgy and Materials group (MMG)

PDF) Analysis Of Residual Stresses And Distortions In Circumferentially Welded Thin-Walled Cylinders

M. VASUDEVAN, Head, Advanced Welding Processes and Modeling Section, B.E, M.E, PhD, Indira Gandhi Centre for Atomic Research, Chennai, IGCAR, Metallurgy and Materials group (MMG)

Materials, Free Full-Text

Metals, Free Full-Text

NATIONAL TECHNICAL UNIVERSITY OF ATHENS

Temperature contour (a) Goldak Double Ellipsoidal (b) Conical (c) CCC

PDF) Determination of heat source model for simulating full penetration laser welding of 316 LN stainless steel by computational fluid dynamics

Surface Tension